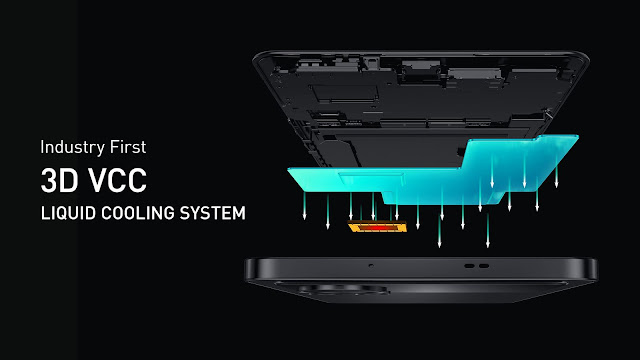

Infinix Launches Cutting-Edge Industry Leading 3D Vapour Cloud Chamber Liquid Cooling Technology

Infinix has officially launched its revolutionary 3D Vapor Cloud Chamber (3D VCC) liquid cooling technology. Using an innovative design on the dimensions of the VC shape, for the first time, the designers achieved an increase in the volume of the chamber, which significantly improves heat dissipation, which leads to better performance. This creative solution fixes some of the issues caused by high temperatures in high-integrated and high-performance smartphones, such as reduced CPU frequency, dropped frame rates and frozen screens. This new technology has been certified by the National Intellectual Property Administration of China.

“Casual smartphone gamers care about performance, while advanced gamers emphasize heat dissipation because of its direct impact on performance. As the 5G era brings new challenges to heat dissipation technology, technological developments are driving innovation from traditional heat pipes to VC, the leap from line to surface base, and now further upgrades from flat surface to three-dimensional base to create Infinix 3D. Liquid cooling in a vapor cloud chamber. This technology not only shows the technical foundation and innovative spirit of Infinix, but also represents a huge step towards technological advancement. ” said Manfred Hong, Chief Product Officer of Infinix.

Infinix's proprietary 3D VCC technology

As heat enters the VC, the water in the evaporator evaporates into steam, which removes the excess heat. The hot vapor then flows into the condenser and becomes a liquid, which flows back to the evaporator through the internal wick structure, which forms a hot and cold circulation system with the coexistence of water and steam.

Compared to the traditional VC design, the 3D Vapor Cloud Chamber Liquid Cooling Technology is a long way forward. Bumps were added to one side of the evaporator, increasing chamber volume and water storage capacity along with heat flow. The water injection volume and Q max values have increased by 20% compared to conventional VCs[1] resulting in a massive overall improvement.

Reducing the thermal resistance of the heating source medium is realized by modifying the structure of the front cover to create a bump that allows the 3D Vapor Cloud Chamber to make almost direct contact with the SoC chip. This significantly reduces the thermal resistance from the shield to the steam chamber, increasing thermal conductivity, performance and heat dissipation. Compared to traditional 2D designs, the new 3D VCC reduces the temperature by about three degrees[2] and the overall heat dissipation performance increases by about 12.5%[3].

The challenges of creating excellence

In order for Infinix to handle heat dissipation in the new 3D VCC design, structural strength had to be significantly improved over previous designs. After numerous tests and improvements, Infinix's R&D team designed a 3D internal structure into a matrix support column that balances the flatness and internal volume of the chamber.

The second major challenge was maintaining the integrity of the wick structure within the 3D structure. Traditional VC wick structures are flat and creases can easily appear in the 3D Cloud transition region, causing potential chamber clogging. By using complicated capillary structure density analysis and advanced welding technology, Infinix's R&D team was able to ensure the integrity of the wick structure, greatly improving performance.

The adaptation of the front cover was also taken into account. In order to reduce the thermal resistance of the media, Infinix's research and development team has repeatedly evaluated the position of the front cover opening and the strength of its alloy material, resulting in the customization of the front cover. Together, these key components form Infinix's proprietary 3D Vapor Cloud Chamber Liquid Cooling Technology.

With this technology built into Infinix smartphones, users can take advantage of superior performance when their device is put under heavy load, allowing them to play games harder and faster, live stream longer and reap the benefits of cooler, smoother and high performance. smartphone.

True to its motto "The Future is Now", Infinix will continue to develop smartphone heat dissipation technology. Infinix will develop a thinner VC with more bumps, with more creative material processes, and even merge the middle frame of the smartphone and the 3D VCC into one, or miniaturize the entire PC cooling module into the smartphone. Driven by a global vision, Infinix will continue to deliver amazing products to customers with its strong innovation capabilities to provide them with the best possible smartphone in their price ranges.

Comments

Post a Comment